Paver Chain

The EPG80G asphalt paver chain is another type of asphalt paver chain that is commonly used in asphalt paving machines. It is similar to the EPG80F asphalt paver chain but with some important differences. The EPG80G asphalt paver chain is designed with a different type of steel and a different heat treatment process, which gives it slightly different properties compared to the EPG80F asphalt paver chain. The G in its name indicates that it has a greater resistance to wear. In addition, the EPG80G asphalt paver chain has a special coating that provides additional protection against wear and corrosion.

The EPG80G asphalt paver chain is also designed to reduce noise and vibration, which can help to improve operator comfort. It is compatible with a wide range of asphalt paver machines and is typically used in high-stress applications where extreme durability and wear resistance are required. Overall, the EPG80G asphalt paver chain is a high-quality, heavy-duty chain that is designed to withstand the rigors of asphalt paving. It offers excellent wear resistance, reduced noise and vibration, and compatibility with a wide range of asphalt paving machines.

Here are some details about the EPG80G asphalt paver chain:

- Size: The EPG80G asphalt paver chain has a length of 80 feet and a width of 1 inch.

- Weight: The EPG80G asphalt paver chain weighs 500 pounds.

- Material: The EPG80G asphalt paver chain is made of high-quality steel.

- Features: The EPG80G asphalt paver chain has a number of features that make it ideal for use in asphalt paving machines. These features include high tensile strength, fatigue resistance, abrasion resistance, and easy installation.

- Applications: The EPG80G asphalt paver chain is used in a variety of applications, including road construction, parking lot construction, and airport runway construction.

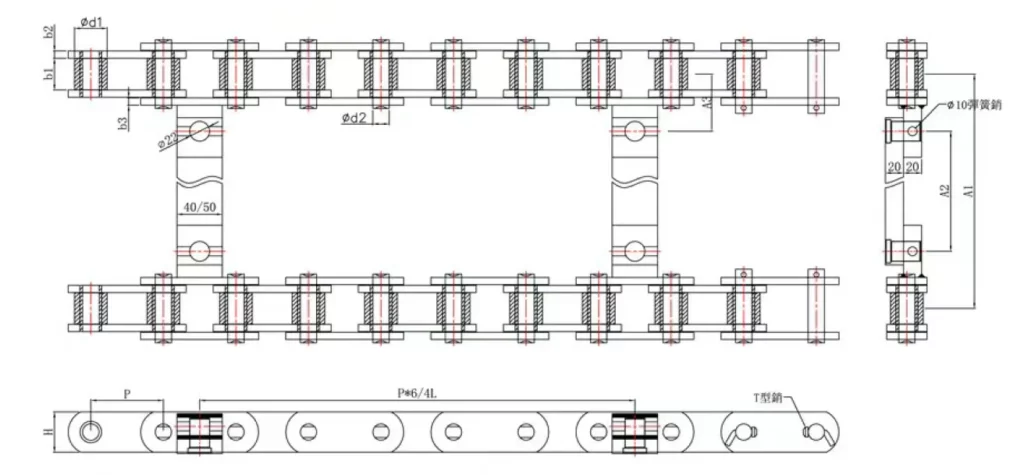

EPG80G Asphalt Paver Chain Dimensions:

| Chain No. | Pitch (P) |

Roller diameter (d1) |

Pin diameter (d2) |

Width between inner plates (b1) |

Scraper Link | Scraper Pitch to Roller Center Distance(A3) | Inner Chain Links (b2) | External Chain Links | Chain Plate Height(H) | |

| External Links (b3) | Scraper Link (b4) |

|||||||||

| EPG80F Chain | 80 | 24 | 15.9 | 26 | 4 | 51 | 8 | 8 | 8 | 38 |

EPG80G Asphalt Paver Chain Features:

The EPG80G asphalt paver chain has a number of features that make it ideal for use in asphalt paving machines. These features include:

1. High tensile strength: The EPG80G asphalt paver chain is made of high-quality steel that has high tensile strength. This means that the chain can withstand the high forces that are generated during asphalt paving.

2. Fatigue resistance: The EPG80G asphalt paver chain is designed to be fatigue resistant. This means that the chain can withstand repeated loading and unloading without breaking.

3. Abrasion resistance: The EPG80G asphalt paver chain is designed to be abrasion resistant. This means that the chain can withstand the wear and tear that is associated with asphalt paving.

4. Easy installation: The EPG80G asphalt paver chain is easy to install and maintain. This makes it a cost-effective option for asphalt paving machines.

The EPG80G asphalt paver chain is a reliable and durable option for use in asphalt paving machines. It is made of high-quality materials and is designed to withstand the harsh conditions of asphalt paving. The asphalt paver chain is also easy to install and maintain, making it a cost-effective option.

EPG80G Asphalt Paver Chain Installation:

The installation process for the EPG80G asphalt paver chain is similar to that of other asphalt paver chains. Here are the general steps involved in the installation process:

Remove the old chain: Before installing the new asphalt paver chain, remove the old chain from the asphalt paver. Make sure to inspect the sprockets, idlers, and other components for any signs of wear or damage.

Prepare the new chain: If the new asphalt paver chain is shipped in a loop, carefully unroll it and lay it out flat. Check the length of the chain to ensure that it matches the length of the old chain.

Thread the chain: Thread the new asphalt paver chain through the sprockets, idlers, and other components of the asphalt paver. Make sure to follow the manufacturer's instructions for the correct routing of the chain.

Adjust the tension: Once the asphalt paver chain is in place, adjust the tension to the manufacturer's specifications. The correct tension will ensure optimal performance and prevent premature wear of the chain and other components.

Lubricate the chain: Apply a high-quality lubricant to the asphalt paver chain to ensure smooth operation and reduce wear. Make sure to follow the manufacturer's recommendations for the type and frequency of lubrication.

Test the machine: After the new asphalt paver chain is installed, test the asphalt paver to ensure that it is operating correctly. Make any necessary adjustments or repairs before using the machine for paving operations.

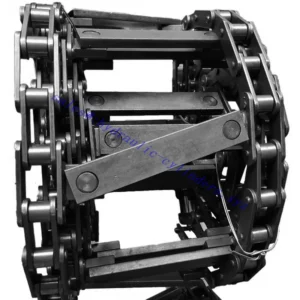

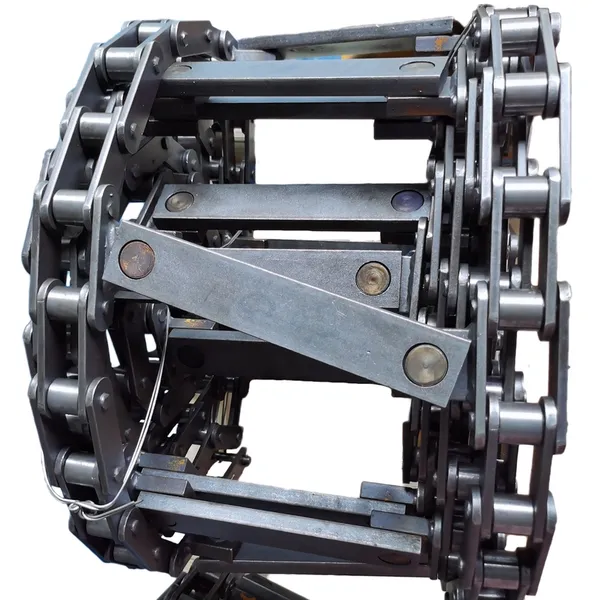

Asphalt Paver Chain Sprockets for Asphalt Paver Chains

Asphalt paver chain sprockets are an important component in the operation of an asphalt paving machine. The sprockets are responsible for engaging with the chain links and driving the conveyor system that moves the asphalt material through the machine.

The asphalt paver chain sprockets are typically made of high-strength steel and are designed to withstand the heavy loads and high temperatures associated with asphalt paving. They come in a variety of sizes and configurations to match the specific requirements of different types of asphalt paver chains.

When selecting asphalt paver chain sprockets, it is important to consider factors such as the pitch and diameter of the chain, the number of teeth on the sprocket, and the tooth profile. Proper selection and maintenance of the sprockets can help ensure the smooth and efficient operation of the asphalt paver.

Regular maintenance of the asphalt paver chain sprockets is also important to ensure their longevity and prevent premature wear. This includes keeping them clean and free of debris, regularly inspecting them for signs of wear or damage, and replacing them as needed.

China Asphalt Paver Chain Manufacturers

We specialize in chains made to customers’ drawings and specifications. Our advantage is reliable quality, competitive price, prompt delivery, and good service. Standard products include various transmission and conveyor chains, like roller chains, double pitch conveyor chains, hollow pin chains, leaf chains, flat top chains, side bow chains, lumber conveyor chains, 81X chains, agricultural chains, CA550 roller chains, S55 roller chains, silent chains, X458 conveyor chains, PIV chains, stainless steel chains, nickel/ zinc plated chain, slient chain, engineering chain, steel pintle chain, welded steel chain, drop forged chain, malleable iron chain, and many other types. Different kinds of attachments are available.

We are one of the best paver chain manufacturers. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Application

Factory tour